Invest-Tech leader in stainles steel cutting

Leader in cutting stainless steel

Laser cutting

Our range:

|

Max. working area: |

1525 mm x 3025 mm |

|

Min. working area: |

0,5 - 16 mm |

We cut different types of stainless steel plates in our production unit in Toruń.

We can cut hot-rolled plates, cold-rolled plates, duplex and heat-resistant steel plates in different dimensions with laser.

Inquiries are priced based on the drawings sent by our clients or created in our design office following client’s approval. Orders may be placed in our headquarters in Toruń or our other offices in Gdynia or Katowice.

Plasma cutting

We cut stainless steel element in different shapes and sizes.

Our range:

Max. plate size 2500 x 6000 mm

Max thickness 80 mm

Standard cutting tolerances (+ chamfer acc. PN ISO 9013-5)::

| Outside diameter | Inside diameter |

| -0/+3 mm | -3/0 mm |

| Outside diameter | Inside diameter |

| -0/+5 mm | -5/0 mm |

Thickness ≥ 60,0 mm

| Outside diameter | Inside diameter |

| -0/+8 mm | -8/0 mm |

Elements are cut acc. EN 10028-7 , EN 10088-2, ASME / ASTM SA 240.

Plate production tolerances acc. PN-EN ISO 18286/PN-EN ISO 9444-2/ PN-EN ISO 9445-2.

WaterJet cutting

Invest-Tech offers watejet cutting technology, where material is cut with a mixture of water and abrasive material used under pressure.

Utilizing this method of cutting, frequently allows to reduce the costs of additional machining. It is a sophisticated offer for particularly demanding customers who work with stainless steel material.

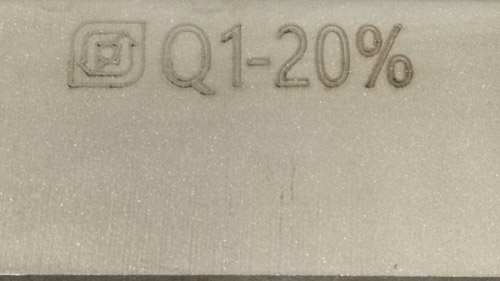

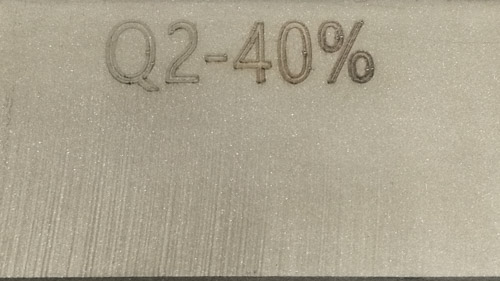

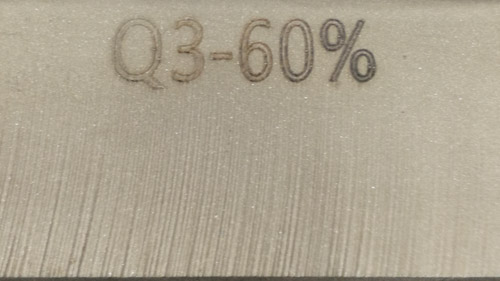

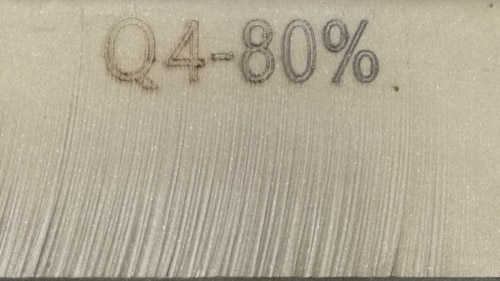

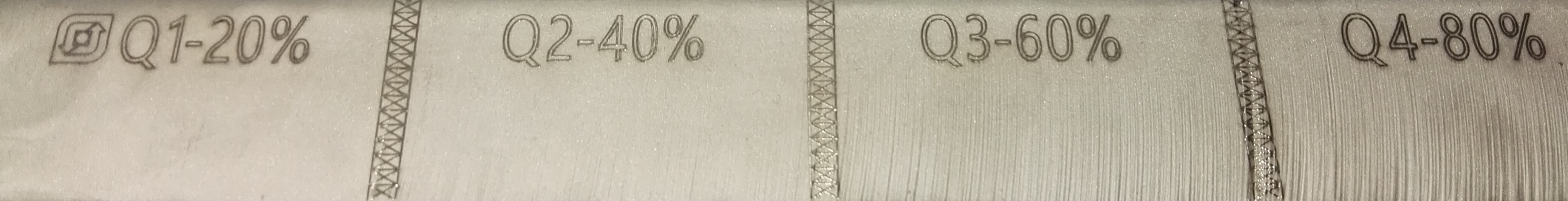

We offer the following cutting quality:

Our range:

| Max. plate size | 2000 x 6000 mm |

| Max. plate thickness | 150 mm |

Waterjet cutting tolerance : +/- 0,5mm + chamfer 0,1/10mm th

Application of waterjet allows to obtain a greater cutting precision, regardless of thickness and shape of the element. Main assets of waterjet technology are:

- great precision of items that are made with utmost care

- avoidance of additional costs connected with machining

- repeatability of items in multi-serial production,

- no temperature changes while cutting ensure preservation of stainless steel properties.

Waterjet cutting is a finely balanced offer adjusted to even particularly demanding customers.

Elements cut per client’s request

Available grades:

1.4307/304L 1.4404/316L 1.4841/310 1.4541/321 1.4878/321H 1.4841/310 1.4571/316TI 1.4547/254SMO 1.4462/LDX 2205 1.4410/LDX 2507 1.4828/309

Cut elements

We cut stainless steel elements of different shapes and dimensions